Принципиальная технология мембранного разделения. Классификация процессов по организации рабочих потоков через мембранный элемент

Pressure-driven membrane separation technologies rely on a difference in pressure from the feed to the product side of the membrane to force water through the membrane. In this manner, water can be recovered from solutions containing both suspended and dissolved solids.

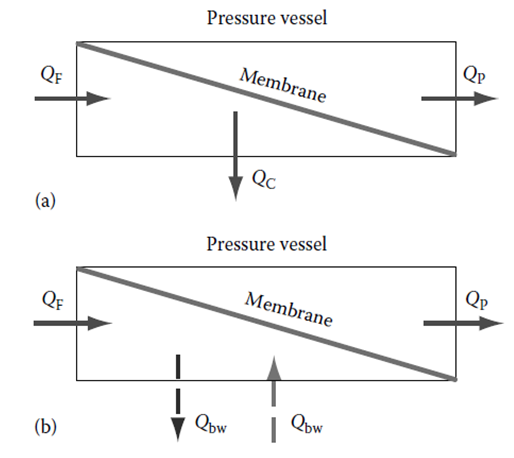

Most MF systems operate in what is called “dead-end” filtration mode. Picture a filtration media (for example, how does a coffee filter work), that allows a fluid (water) and some coffee grounds to pass through but retains the bulk of the coffee grounds. See Figure 1

Figure 1. Dead-end membrane filtration

Flows: QF – feedwater; QP – permeate (filtrate); Qbw – backwashing water, intermittent

Dead-end MF systems are cleaned using two techniques: online backwashing and clean in place (CIP). Online backwashing involves intermittent backwash with filtered water plus an air pulse to help lift solids off the membrane. Backwashing can occur once every 15 to 60 min, depending on the concentration of solids in feedwater (higher concentration results in more frequent backwashing). CIP is performed as needed to remove materials from the membrane that backwashing does not.

Figure 1. Cross-flow membrane filtration

Flows: QF – feedwater; QP – permeate (filtrate); QC - concentrate

Some MF systems operate in cross-flow filtration mode rather than dead-end filtration. Figure 8.3 depicts a cross-flow pattern across a membrane. In cross-flow filtration, feedwater flows tangentially across the surface of the membrane and not all water sent to the membrane actually permeates it. Hence, cross-flow filtration results in one influent stream but two effluent streams (versus a single effluent stream for dead-end filtration). The rationale behind cross-flow filtration is that fluid traveling tangentially to the membrane surface essentially scours the membrane surface free of solids that might foul the membrane. Hence, cross-flow filtration is, in theory, a continuous operation, rather than a batch process. In practice, however, the membrane is fouled enough with time to warrant an occasional CIP to remove solids from the membrane.

Дата добавления: 2020-04-12; просмотров: 647;