Other lathes and turning machines

In addition to the engine lathe, other turning machines have been developed to satisfy particular functions or to automate the turning process. Among these machines are (1) toolroom lathe, (2) speed lathe, (3) turret lathe, (4) chucking machine, (5) automatic screw machine, and (6) numerically controlled lathe.

The toolroom lathe and speed lathe are closely related to the engine lathe. The toolroom lathe is smaller and has a wider available range of speeds and feeds.

The speed lathe is simpler in construction than the engine lathe. It has no carriage and cross-slide assembly, and therefore no leadscrew to drive the carriage.

A turret lathe is a manually operated lathe in which the tailstock is replaced by a turret that holds up to six cutting tools.

As the name suggests, a chucking machine (nicknamed chucker) uses a chuck in its spindle to hold the workpart.

A barmachine is similar to a chucking machine except that a collet is used (instead of a chuck), which permits long bar stock to be fed through the headstock into position. Bar machines can be classified as single spindle or multiple spindle (Fig 5.5).

Figure 5.5 - (a) Type of part produced on a six-spindle automatic barmachine; and (b) sequence of operations to produce the part: (1) feed stock to stop, (2) turn main diameter, (3) form second diameter and spotface, (4) drill, (5) chamfer, and (6) cutoff.

The modern form of control is computer numerical control (CNC), in which the machine tool operations are controlled by a ‘‘program of instructions’’ consisting of alphanumeric code. Today, automatic chuckers and bar machines are implemented by CNC.

CAM part program creation and data management. Three types of part geometry. Program creation. CNC controls

Boring machines

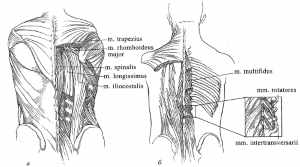

It uses a single-point tool against a rotating workpart. Boring is performed on the inside diameter of an existing hole of an existing cylinder. Boring mills can be horizontal or vertical. In a horizontal boring operation, the setup can be arranged in either of two ways. The first setup is one in which the work is fixtured to a rotating spindle, and the tool is attached to a cantilevered boring bar that feeds into the work, as illustrated in Figure 5.6(a). The boring bar in this setup must be very stiff to avoid deflection and vibration during cutting.

(a) boring bar is fed into a rotating workpart, and (b) work is fed past a rotating boring bar.

Figure 5.6 – Two forms of horizontal boring:

Дата добавления: 2017-05-02; просмотров: 1078;